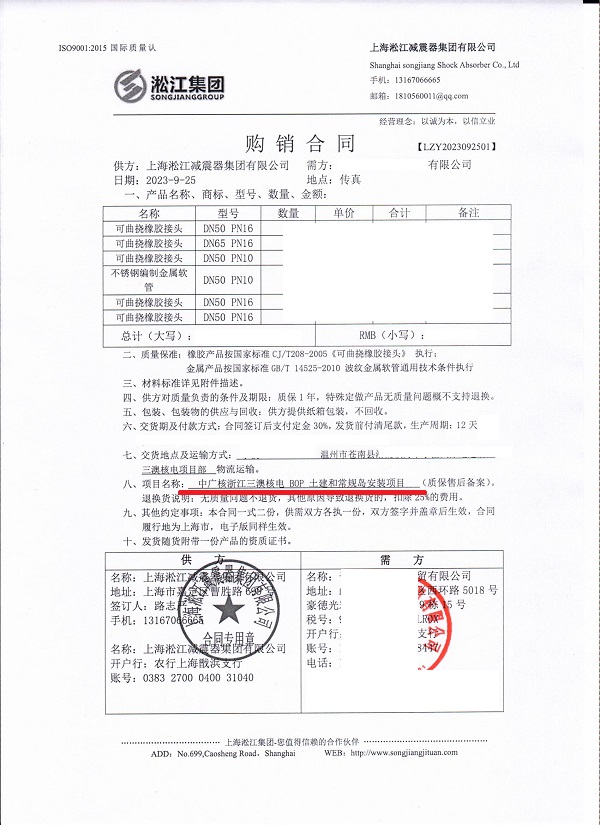

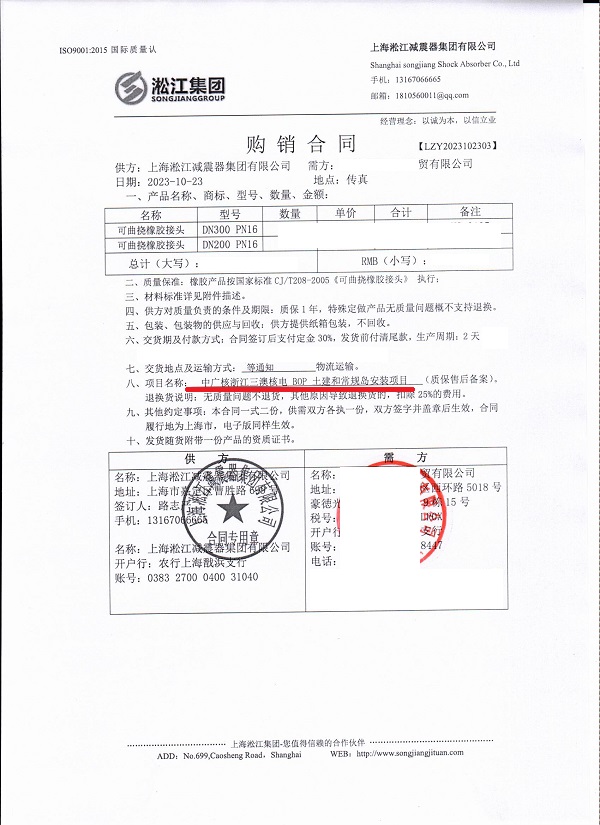

Shanghai Songjiang Group supplied high-quality rubber joints for the CGN Zhejiang San’ao Nuclear Power BOP Civil Engineering and Conventional Island Installation Project, meeting the stringent engineering requirements of the nuclear power plant. This project planned a total of six nuclear units utilizing the “Hualong One” technology, with Units 1 and 2 of the first phase starting in 2020 and 2021, respectively. “Hualong One” is a third-generation nuclear power technology developed independently by China, with a design lifespan of 60 years, combining both active and passive safety systems for enhanced operational safety.

With years of production experience, Shanghai Songjiang Group ensured that the rubber joints provided for the San’ao Nuclear Power Project met international quality standards and were certified for use in the nuclear industry. These rubber joints, made from premium rubber and high-strength flanges, exhibited excellent corrosion resistance and high-temperature performance, allowing them to operate stably over long periods in complex environments. Given the high safety and durability demands of nuclear power facilities, the rubber joints play an indispensable role in the system.

With years of production experience, Shanghai Songjiang Group ensured that the rubber joints provided for the San’ao Nuclear Power Project met international quality standards and were certified for use in the nuclear industry. These rubber joints, made from premium rubber and high-strength flanges, exhibited excellent corrosion resistance and high-temperature performance, allowing them to operate stably over long periods in complex environments. Given the high safety and durability demands of nuclear power facilities, the rubber joints play an indispensable role in the system.

The successful implementation of this project not only earned Shanghai Songjiang Group a strong reputation in the nuclear power sector but also strengthened the company’s competitiveness in high-end engineering projects. The high performance and stability of the rubber joints contributed significantly to ensuring the safe operation of the nuclear plant, facilitating the smooth progress of the project.

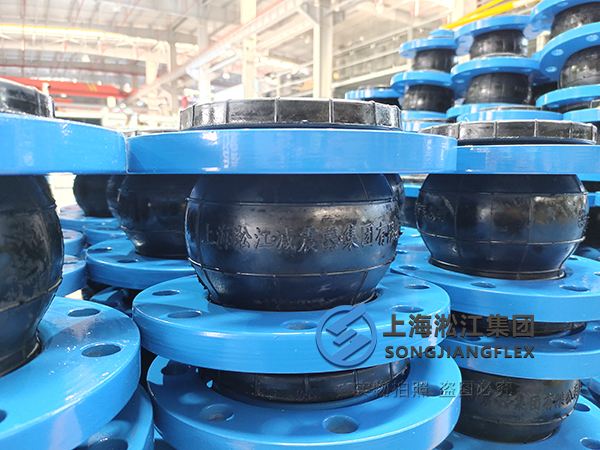

Delivery Photos of the Rubber Expansion Joint:

Delivery Photos of the Rubber Expansion Joint:

Our company’s new website is now live, featuring the latest product introductions. For more details, please visit

Our company’s new website is now live, featuring the latest product introductions. For more details, please visit

![[Qinghai Everest Insect Herbs Industry Co., Ltd.] Use favorable shock insulating effect 316 stainless steel Metal Flexible Hose Contract](https://www.rubber-expansion-joint.cn/wp-content/themes/xsmake.sj/timthumb.php?src=https://www.rubber-expansion-joint.cn/wp-content/uploads/2022/06/Introduce-Qinghai-Everest-Insect-Herbs-Industry-Co.-Ltd.-Use-favorable-shock-insulating-effect-316-stainless-steel-Metal-Flexible-Hose-Contract316-stainless-steel-Met-1.jpg&h=400&w=500&zc=1)