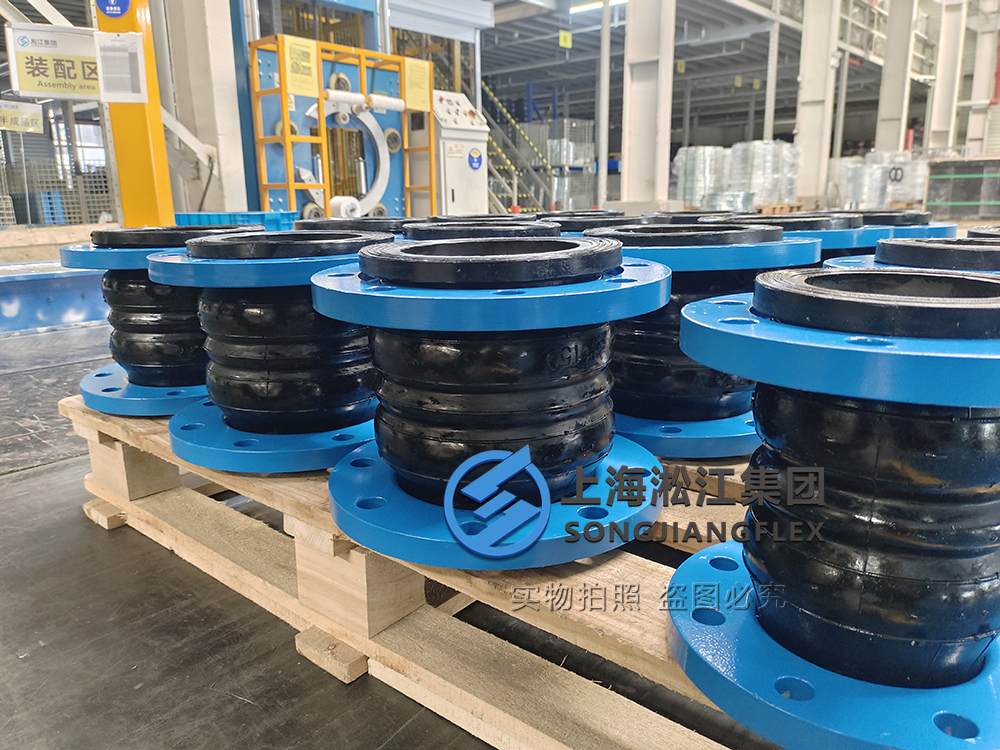

What is a Double Sphere Rubber Expansion Joint?

A double sphere rubber expansion joint is a flexible pipe connector made from molded rubber with two spherical arches. It is designed to absorb axial, lateral, and angular movements while reducing system vibration and noise.

Compared to a single sphere joint, the double sphere design offers a longer body and greater movement compensation. It is ideal for HVAC, fire protection, water treatment, and pump discharge systems that require higher flexibility.

When integrated into a system, the rubber expansion joint for pipe helps reduce stress on equipment, supports better alignment, and prevents leakage under pressure.

Why is the Double Sphere Design More Advantageous?

The dual arch structure significantly improves the joint’s flexibility and vibration absorption. The additional rubber volume and surface contact help reduce the overall force transferred to connected equipment.

This design is particularly effective in systems with compressors, pumps, or high-pressure fluctuations. It provides extra shock absorption and insulation, extending the lifespan of surrounding components.

The double sphere model is a top-performing variant of flexible hose packless expansion joints, offering optimal performance for vibration-sensitive environments.

Where is a Double Sphere Rubber Expansion Joint Commonly Used?

Double sphere rubber expansion joints are widely used in HVAC systems, chilled water loops, wastewater pipelines, industrial machinery, and cooling towers. They are especially effective at pump connections where vibration and noise isolation are crucial.

Their flange connection makes them easy to install, align, and replace, even in systems with limited maintenance access.

This joint type plays a critical role in equipment rooms, water pump stations, and industrial facilities that require system durability and operational safety.

How Should a Double Sphere Rubber Expansion Joint Be Installed?

Proper installation is essential to ensure durability and optimal performance. Make sure the flanges are aligned and the bolts are not over-tightened to avoid damaging the rubber body.

Follow rubber expansion joint installation guidelines, such as using a cross-bolt tightening method to evenly secure the joint. Proper anchoring and support of the connected pipe system are also important.

Where needed, vibration isolators or spring mounts can be used in conjunction with the joint to minimize system oscillation and noise.

What is the Difference Between Single Sphere and Double Sphere Joints?

Single sphere joints are compact and cost-effective, suitable for systems with limited space and minor movement requirements. However, they offer less movement compensation than double sphere models.

Double sphere joints are longer, more flexible, and absorb greater displacement. They’re ideal for systems exposed to frequent thermal expansion, vibration, or movement.

Choosing between them depends on system dynamics and space constraints.

What Materials are Common in Double Sphere Joints?

The rubber body is typically made from EPDM, NBR, or NR, selected based on the system’s fluid and temperature range. EPDM is ideal for hot water and steam, NBR for oil-based fluids, and NR for general water supply.

The flanges are usually made of carbon steel or stainless steel, with internal reinforcement from nylon or polyester to enhance pressure resistance.

In corrosive environments, consider pairing with flexible hose packless expansion joints or using PTFE-lined variants for added protection.

How Long Do Rubber Expansion Joints Last?

Under normal conditions and proper installation, a double sphere rubber expansion joint can last 5 to 10 years. Lifespan depends on operating pressure, fluid type, and environmental conditions.

Regular inspection for surface cracking, aging, or leakage is recommended. Avoid over-pressurizing or using incompatible fluids, as these reduce lifespan significantly.

For systems exposed to high vibration, periodic replacement of rubber union connector expansion joints is advised to maintain safety and performance.

Do Rubber Expansion Joints Require Extra Gaskets?

In most cases, no. The rubber body of the joint itself provides an effective seal when properly compressed between flanges. However, if the flange faces are corroded or uneven, additional gaskets may be used.

Avoid applying sealing compounds or multiple gaskets, as this can hinder the joint’s flexibility and increase stress on the material.

Maintaining flat, clean flange surfaces and even bolt tension is more important than adding extra sealing materials.

What is the Purpose of Rubber Expansion Joints?

Rubber expansion joints are designed to absorb pipe movement, reduce vibration, and isolate mechanical noise. They also compensate for misalignment and protect sensitive equipment from stress due to thermal expansion or system dynamics.

These joints provide long-term system stability and reduce maintenance costs, especially in applications involving frequent load changes.

They’re essential in piping systems that cross structural expansion joints, traverse buildings, or experience pressure surges.

What is the Purpose of an Expansion Joint?

An expansion joint’s primary role is to accommodate thermal expansion, absorb vibrations, and compensate for mechanical displacement in pipelines.

They help avoid damage caused by system shifts, misalignment, or pressure fluctuations, ensuring operational safety and system longevity.

Whether in HVAC, chemical processing, or municipal water lines, expansion joints help maintain pipe system integrity over time.

What is an Elastomeric Expansion Joint?

An elastomeric expansion joint is a flexible connector made from synthetic rubber materials like EPDM, NBR, or neoprene. These materials allow the joint to expand, compress, and flex without cracking or losing shape.

Elastomeric joints offer superior vibration damping, corrosion resistance, and long service life. They are widely used in potable water, sewage, oil, and chemical applications.

They are cost-effective, lightweight, and easy to install compared to metal joints, making them a common choice for modern piping systems.

What Are the Three Types of Expansion Joints?

The three primary types of expansion joints include:

-

Rubber Expansion Joints – for flexibility and vibration isolation in piping systems.

-

Metal Expansion Joints – used in high-pressure and high-temperature environments, often in power plants.

-

Fabric Expansion Joints – used in low-pressure duct systems and exhausts for their flexibility and corrosion resistance.

Each type serves different operating conditions and performance requirements, and selecting the right one depends on the fluid, pressure, temperature, and movement range.

Conclusion

A double sphere rubber expansion joint is a durable, high-performance solution for absorbing movement and vibration in piping systems. Its dual-arch design enhances flexibility, reduces stress on equipment, and ensures stable long-term operation across industrial and commercial applications.